City wastewater treatment is vital for providing a safe, drinkable supply to local populations. Public utilities companies have a responsibility to ensure they treat municipal water so people feel confident drinking from the tap. Authorities monitor the water treatment process to check that potential contaminants never pose a serious threat to human health. Water passes through several treatment stages before it ever reaches your workplace. But is conventional water treatment enough to filter the range of pollutants, including heavy metals, organic material, and human-made toxins, from our drinking water?

The importance of treated drinking water in the workplace isn’t new knowledge to managers, but it should still be a top focus. Raw water must go through a complex system of treatment stages to remove impurities, bacteria, and parasites and make it drinkable. We fill a glass from the tap, then assume that clean water is safe enough to drink, but have you considered the treatment process of drinking water?

Read on to learn more about the water treatment process — and whether our municipal water is enough to keep employees hydrated, healthy, and happy in the workplace.

Why Does Water Need to Be Treated?

Local water companies get their supply from surface water and ground water, which are open to environmental contaminants and liable to become polluted.

Surface water includes lakes, rivers, and streams. Over two-thirds of the American population rely on surface water as their primary water source. Rainwater runoff from farms can wash nitrates and pesticides into waterways and the drinking water supply. Groundwater sources include aquifers and underground lakes that collect rain that seeps through cracks and pores before accumulating in pockets between the rocks that sit deep within the ground. Utility companies tap groundwater where there isn’t enough supply of surface water to service the community. As water trickles through rocks, it can carry heavy metals like arsenic into underground aquifers.

Previous incidents, such as the decades of leaching arsenic and other toxic substances into groundwater in the midwest and southeast, prove that millions of unaware people may be drinking contaminated water. In these instances, although seemingly considered innocuous, the water treatment process isn’t enough to guarantee clean water free of contaminants.

The EPA enforces Safe Drinking Water Standards on U.S. water quality to ensure it’s safe for consumption. These guidelines require drinking water to adhere to maximum levels for over 90 separate contaminants. Some of the most common pollutants removed from drinking water through the water treatment process are bacteria, viruses, protozoa, and algae. Other types of contaminants include dissolved minerals such as salts and metals, organic chemicals such as pesticides or herbicides, and even radioactive substances.

So should tap water be filtered even further for our employees? Some knowledge about the water treatment process itself can help you make this decision for your workplace. Read on to learn more.

The 4 Stages to Clean Water

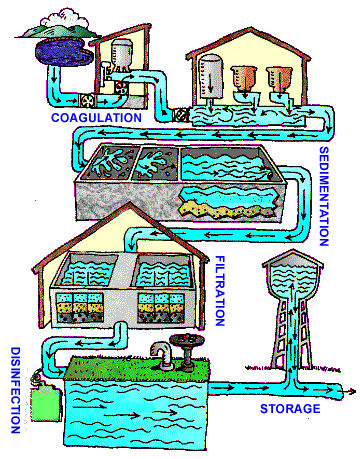

There are multiple systems in place to prevent diseases and contaminants from entering our water supply. Water goes through a rigorous filtration procedure to ensure the removal of any compound that could pose a threat to our health. This treatment process involves 4 stages that help provide safe drinking water to homes and businesses across North America.

- Coagulation and Flocculation: This uses chemicals that bind with other waterborne compounds to form larger particles, which create a solid mass called ‘floc’.

- Sedimentation: As floc is denser than water, it drifts to the bottom of the water treatment tank during a sedimentation process, settling in a removable layer.

- Filtration: Once the suspended floc has been removed, the residual clear water is passed through sand, gravel, or charcoal filters that take out dissolved particles, parasites, bacteria, viruses, and toxic chemicals.

- Disinfection: The final water treatment stage is disinfection with chlorine. This process not only removes the remaining pathogens but keeps the water supply clean as it passes through the pipeline.

The use of chemicals to treat water is a controversial topic. Some people believe that it is the best way to make sure that water is safe for consumption, while others feel that it can be harmful to humans and animals.

Chemicals are used in the treatment process because they are considered more effective than other methods of removing contaminants. They also have a higher success rate than other techniques when it comes to removing pathogens from drinking water. The use of chemicals has been proven to be safe for humans and animals as long as they are used in accordance with guidelines set by the EPA and FDA. We’ll touch a little more on this in the next section.

The Benefits of Water Treatment

While all municipal water supplies pass through a standard treatment process, the water at your business may undergo different levels of treatment depending on where your water comes from. For example, surface water needs a higher level of coagulation, sedimentation, and filtration than groundwater because water taken from lakes, rivers, and streams is likelier to contain more sediment and higher levels of contaminants than naturally-filtered groundwater.

Hydration fuels productivity, therefore, employees must have access to safe drinking water. The Occupational Safety and Health Administration enforces this vital requirement. Ensuring workplace water safety is a highly important task, and for the most part, we can deem tap water safe enough to drink. Every water supply requires disinfection to guarantee its quality. Typically, the treatment process uses chlorination, chloramines, ozone, or ultraviolet light to disinfect.

While 64% of US community water treatment systems use chlorine as a disinfectant to remove pathogens, a sometimes off-putting taste and increased risk of cancer may prevent employees from drinking chlorine-treated water. Ozonation can also be used to remove pathogens from the treated water supply. However, chlorine is still required as ozone cannot keep a supply contaminant-free once it has left the treatment plant. This is why it can be beneficial to complete the ozonation stage directly.

So, what’s the healthiest way to treat water? Let’s take a closer look.

Is Water Treatment Always Successful?

Despite the standards and rigorous supervision, water treatment isn’t always effective. In 2022, Jackson Mississippi’s water crisis got so bad that citizens couldn’t flush their toilets and the city temporarily ran out of bottled water. According to CNN, years of water system issues finally led to the failure of their entire water treatment system after being hit with heavy rainfall. Many compared the issue to that which happened in Flint, Michigan when lead-contaminated water led to a water crisis in 2014.

Perfluoroalkyl and perfluoroalkyl substances (PFAS) or “forever chemicals” have become an increasing concern in workplaces across the country. Many industries use PFAS on a daily basis, which might affect our drinking water more than we considered in the past. There are actually almost 11,000 PFAS in constant use, and much cannot be removed from the city’s treatment process alone.

Other common drinking water toxins, like lead, continue to be a popular reason why many choose to filter their water prior to consumption. As infrastructure continues to age in America, the threat of lead contamination or even poisoning is increasingly high. When ingested in large amounts, lead can cause a myriad of chronic health problems or even death.

Quench Water Dispensers Provides Clean, Safe Drinking Water

There’s only one way to ensure your water supply is entirely safe — that is to install an advanced water filtration system where your employees fill their glass. The advantages of a well-hydrated, healthy, productive work team are worth the investment.

A Quench water dispenser uses an array of technologies to ensure your water supply is clean, starting with quenchWATER+ filtration technology that reduces chlorine, lead, pesticides, and organic matter through multiple filtering processes, including sentiment, pre-carbon, reverse osmosis, and polishing.

Water treatment is an important step in maintaining a healthy and safe environment for employees. There are many benefits to having a water treatment system installed in the workplace. These include:

- Reducing the risk of contamination due to bacteria, viruses, and other microorganisms

- Increasing productivity by reducing fatigue and discomfort

- Improving employee morale by providing fresh-tasting drinking water

- Lowering maintenance costs with an increased lifespan of your equipment

Guarantee that your workforce’s water supply is free from harmful levels of contaminants. Contact Quench USA, and our expert customer service agents will recommend the countertop or freestanding bottleless water dispenser to protect your office.

Get a free quote on any of Quench’s bottleless water filtration systems today!